BIOGRAPHY OF GILBERTO TANI

FOUNDER OF OIL SERVICE

WORK’S WORLD

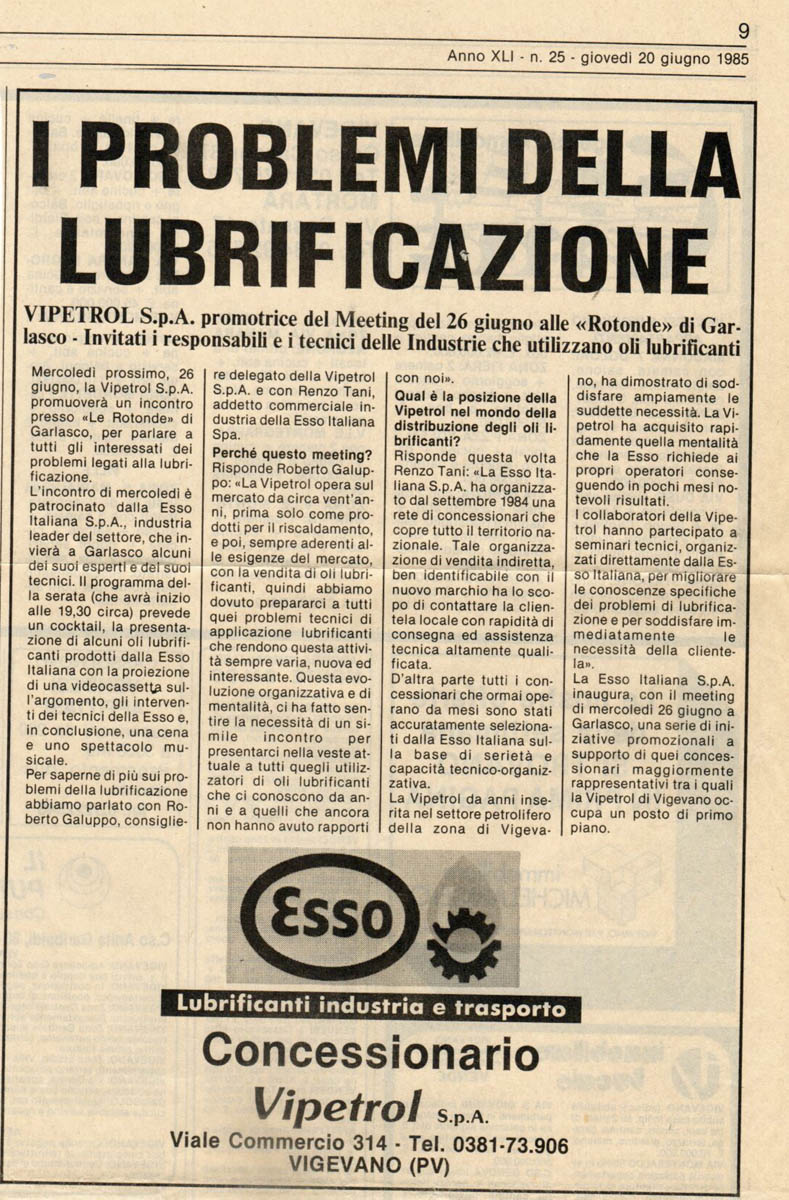

It is 1986, I am 20 years old, I follow Analysis 2 in Electronic Engineering and during the lessons I dream about the world of work. Sometimes my father takes me to the office with him, so I watch him manage large orders as an Esso Italian manager (head of the Lubricants Industry section) and I fall in love with customer calls, sending orders by post, preparing important meetings …

The work of the “salesman” attracts me and I can’t resist it, and a few months later I start in Petrol Team, Esso dealer for the sale of lubricants, that is looking for a willing young man.

My dad teaches me a few tricks of the trade and lets me break the ice as a technical salesman.

The first visits to customers begin with my legendary 2 Cavalli red, jacket and tie and gelled hair. I love this role!

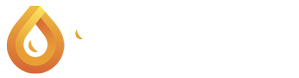

A very young Renzo Tani just hired at the Italian Company Esso

THE DISCOVERY OF DIATHERMIC OIL

After a year I move to Vipetrol, a more structured dealer where I can work alongside experienced salespeople who fill me with advice, strategies, teach me how to set up sales proposals … Everyone knows and appreciates my dad, so they are happy to reciprocate by mentoring me, his son. At the same time, I try to learn as much as possible because I want to stand out from the others, I want to grow professionally and I try to seize every opportunity because I have a dream that is being born, even if it is not yet the time to realize it.

Once the owner Mr. Galuppo even made me travel in a tank truck to deliver a load of fuel oil to Bergamo: he wants me to touch every aspect of the company, including logistics and transport.

It was in that period that I discovered diathermic oil. It is a different oil from other lubricants, it is delivered in bulk and not in drums, in very large quantities, and offers excellent margins.

I continue to follow everything else and, despite I have to leave for one year due to the military service, I put everything into learning what it takes to start selling supplies of diathermic oil.

It is a fascinating uncharted territory!

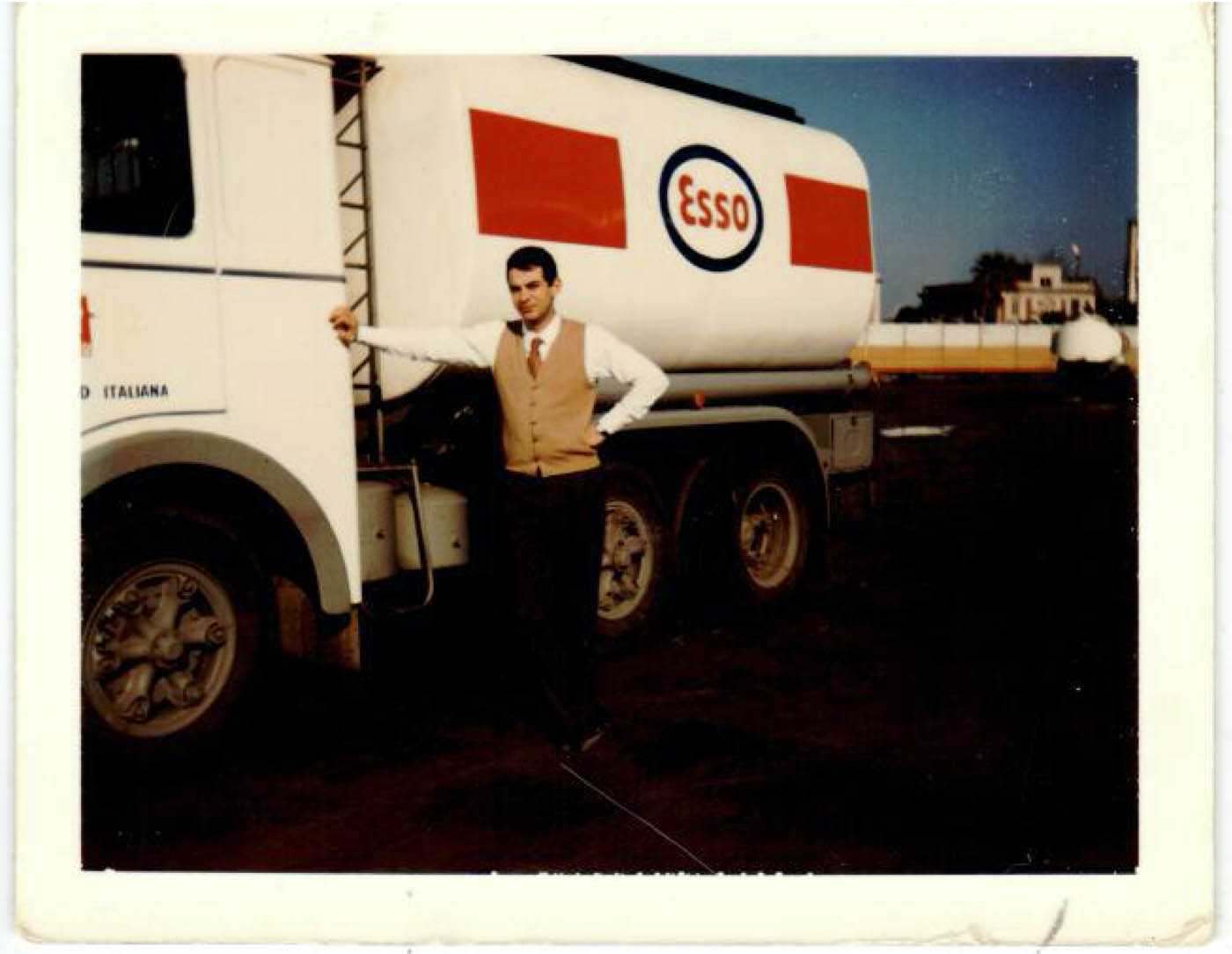

The executive Renzo Tani during a conference

SPECIAL OPERATIONS

A problem arises: those who buy new oil must also face the problem of changing oil: draining, disposing of old oil, loading new oil, cleaning, bleeding and commissioning.

How can I do?

I set up a small intervention team, put on my overalls and attend every stage of the unloading and loading operation, both to check the quality of the work and to learn the secrets of the trade.

During our first intervention, it is crazy cold at the Tintoria Industriale Serio, and also due to anxiety, I vomit in the bathroom of the restaurant where the workers are having lunch.

Despite the concern, however, everything goes smoothly and it is my first triumph in the field: 20,000 liters unloaded, disposed of, loaded, cleaned and vented: a success!

Time passes, together with my father I create the first pump-machine for diathermic oil useful for speeding up the unloading and loading operations, and I make one sale after another.

I take my owner’s company to a new market and generate unexpected profits, but I only get pats on the back.

I understand that my work will never be recognized financially and one Friday in March I decide to leave.

My dad is on a rampage but I don’t change my mind: the following Monday I resign, I buy a “diesel truck”, I load the machine-pump (to which I had applied a lanyard to move it more easily), and I go to Casteggio to rent a small warehouse.

It is 1991 and Oil Service is born!

Gilberto Tani’s early work in overalls on the field.

THE BATCAVE

The early days are exciting but hide pitfalls.

I need clients, so I work many hours calling all the companies (thanks to one of the first cell phones as big as a brick) that have or could have a diathermic oil system. I am now trained to sell and I immediately create interesting business relationships.

For the interventions I have no employees, the company is too small to have permanent staff. So I put on the suit and with 1-2 collaborators, and some Saturdays also with my dad, we move to the sites to carry out the work.

The technical problems, on the other hand, are more complex: customers ask for the diathermic oil maintenance service, so it is necessary to filter the oil to remove sludges and gas. All of this while they are extremely hot.

I don’t have the tools and they certainly can’t be found on the market: it’s up to me to build them!

With the help of my dad, I design and assemble the first filter cart for sludges, complex but feasible.

The degasser on the other hand is the real challenge: it requires several laboratory experiments, assemblies with different types of valves, a vacuum pump and tests at different temperatures. The first field test does not go well, but thanks to the experience of Mr. Guida (titanic maintenance worker of 2 meters for 120 kg of a large company in Mortara) I manage to fine-tune it: we can face the interventions!

I work all over Italy and it often happens that clients have an emergency even in the middle of the night. So from wherever I am I run to Oil Service, change like Bruce Wayne in the batcave, load the van with all my gadgets and leave. Lucca, Como, Caserta, Foggia … wherever they call me, I’m coming! I remember more than one August (typical month for industrial maintenance) traveling in the company van with my partner. The sandwiches, the hotel preferably on the sea, at least since I leave to work at 6:30 am then I can reach her on the beach at 4 pm, and thus swimming together in the sea.

The first Oil Service van and the photographic testimony of one of the first interventions on a trip to the port of Genoa on a Grimaldi ship.

LIKE THE PHOENIX

The turning point for Oil Service came in 1997 following a stormy quarrel with a supplier. He wants to grow: he plans to hire and manage technicians who, in addition to supplying the diathermic oil, also carry out loading and filtering; so he asks me to make commercial agreements with my competitors, so as to allow him to become a leader in the sector.

On the other hand, I have growth projects for Oil Service and even if we are still “small” (we have just expanded into a 200sqm warehouse) I have no intention of being blackmailed by the larger and older companies by freezing the status quo. A bitter trade war begins, and the supplier, which has been on the market for over 20 years, tries to make scorched earth around me, diverting all contacts to those who guarantee absolute loyalty.

Here comes the turning point: I raise the bar by hiring the first employee after my wife, I double up vans and warehouses, and I do what no one else in the industry has yet dared to do: I rebuild all the steel machinery to make them aesthetically beautiful, as well as more resistant and functional.

In the meantime, I equip the company with a marketing system that is more up to date, since thanks to the employees I have more time to work on promotion and sales.

Gilberto Tani and Ciccio intervene at Ferrari in Maranello. In the background some racing cars of the time.

THE STRATEGY IS SUCCESSFUL

To tell it it seems like a gamble but I know the market and my competitors, I know how technologies work and although risky, the move quickly brings us closer to the next goal that I have set myself.

In August of the same year, in fact, the contract employees are more than before, they rotate to support the peak of summer work, and they are all happy to be called back more and more often.

I manage to steal jobs from all competitors and I also take Italplastic Spa as a customer, a leading textile company in the Como area: 40,000 liters of oil replaced in 5 days with Ciccio’s team; Alberto my plumber friend; Alessandro known as “Il Cubano” for his Caribbean origins, Franco friend and maintenance manager in a Pavia company; and Lamberto, my neighbor’s handyman mechanic.

What days!

We also work in Croatia with Lamberto, and he takes his wife and daughter to go for a swim after work, combining useful and enjoyable.

From 8:00 to 17:00 head to work, then everyone is free to swim in Croatian waters!

The vans become two, and work is carried out at Italplast, a large company in the Italian plastic sector.

The great Oil Service operational team in full: Lamberto, Ciccio (Alberto), Il Cubano (Aleandro), Gilberto Tani and Franco.

MY FIRST MILLION TURNOVER

The escalation of these years is the result of two lines of growth that have accompanied me since the company was founded: commercial training and technological research.

COMMERCIAL TRAINING

In 2010 I entrusted myself to Franco Righetti, trainer and communication expert, who at the first lesson tells me: “Ask me a question that raises a problem that you can solve”. It seems the phrase of Jordan Belfort the famous Wolf of Wall Street, yet Franco with patience and competence for 4 years, twice a week, teaches me “everything”: approach, stimulation, objections, slogans, company presentation.

In those years Oil Service equips itself with brochures and its first Company Profile.

From that moment on, all the people who work with me always receive training, sometimes commercial and sometimes technical, depending on the role they hold.

At the end of the 4 years Franco greets me by saying “I’m not leaving a client, but a friend and trainer”. Simply the best compliment I could ever get.

Gilberto Tani and Franco Righetti in 2010.

TECHNOLOGICAL RESEARCH

The second growth driver of Oil Service is technological research. Every year the machines are improved, and when we get to the physical limit of the technology I start investing in automation and patents. Automatic measuring instruments are created, the collaboration with the Chemistry Department of the University of Pavia, the Oil Service patents, a new line of diathermic oils and additives with cutting-edge chemical-physical characteristics.

An example? The current filter pumps, born after the research of those years, run faster than the engine of a Ferrari!

This power allows us to really filter all the oil in a system even 3 times in the same amount of time that my competitors are able to do only the first filtration.

“I AM IRON MAN” cit.

As you may have noticed by reading so far, work for me is not a question that stops at the office door, but it is an all-encompassing passion, which in overcoming challenges (and bad luck) makes me satisfied with the results.

It is 2016, I am 50 years old, and I have a goal, this time a personal one: to engage at a tough but also very mental sport like Triathlon, and be able to finish a sprint race in a few months and the famous Iron Man 70.3 in two years. Triathlon requires great self-discipline because the race lasts many hours, and the muscles alone are not enough to withstand the effort. I therefore rely on the training of a great champion from Pavia, Andrea Re, 8 times World Champion and former Italian Olympian, now a triathlon coach.

3 years later in 2018 I closed the Iron Man 70.3 in Nice with a time of 6 and a half hours (with an inflamed tendon).

The following year in 2019 I finish my second Iron Man 70.3 in Cervia in 6 hours flat.

I believe that my passion for triathlon will never end.

I crossed the finish line of my first IronMan 70.3 in Nice.

ALGORITHM AND THE NEW OIL SERVICE

It is the winter of 2018, a doubt is growing wider in my head, and it begins to haunt me.

We live in the years of molecular physical simulations, quantitative marketing, even trading on the stock exchange takes advantage of quantitative systems for the choice of investment timing.

So why in order to evaluate the maintenance interventions on the plants everyone takes the precise laboratory analysis and interprets them by nose like the fortune-tellers when they consult the tea residues or the Ching chopsticks?

I consult prof. Zanoni of the Chemistry Department of the University of Pavia and I ask him for an opinion on the matter. The prof is excited at the idea of challenging the status quo of the sector and decides to accept the challenge.

Researchers have a goal: the physical formula of Thermal Efficiency, the Holy Grail of Diathermic Oil.

RESEARCH AND THE FUTURE

The challenge is tough, it requires over 450 precise data from interventions on as many different diathermic oil systems. Chemical analysis data before and after the intervention, consumption data, power output. It is not easy to collect all the data but in order to obtain the result, the customers who participate in the study obtain discounts and pre-emption on the new maintenance system.

After 2 years the research is complete and today 18 physical quantities are needed to calculate the thermal efficiency of a diathermic oil system.

But now, for the first time in Italy, we can know in advance and precisely which types of interventions on a system generate the best possible maintenance result.

Hence the story of my future, and of Oil Service.